Research

The Benhabbour Lab research focuses on the engineering of novel, tunable, polymer-based delivery platforms for the treatment and prevention of disease. Our work combines the elegance of polymer chemistry with the versatility of engineering and formulation development to design and fabricate efficient translatable multipurpose prevention technology (MPT) delivery systems for a wide range of applications including cancer treatment, HIV prevention, osteoporosis, and regenerative medicine.

3D Printed Intravaginal Ring (IVR) Platform Technology – Next Generation Multipurpose Prevention Technology (MPT) IVRs

Our lab is pioneering the development of the next generation MPT IVR that is prospectively conceived, designed, constructed, tested and manufactured, in a rational development path that implements state of the art drugs, materials, performance evaluation and manufacturing methods. Particular advantages to our device and methodology are: 1) it is manufactured using state-of-the-art 3D Continuous Liquid Interface Production (CLIP™) printing; this enables diverse device geometry and biophysical properties, efficient drug loading & controlled release, and sound, automated manufacturing with good process control; 2) use of a proprietary drug loading process disassociated from the fabrication process to allow formulation of a wide range of drugs including biologics. These IVRs are currently being develop as the next generation MPT for prevention of HIV, HSV, and unplanned pregnancy.

Ultra-Long-Acting Tunable Biodegradable and Removable Controlled Release Implants for Drug Delivery

Our lab has pioneered the development of an ultra-long-acting injectable formulation that forms an in-situ forming implant (ISFI) once injected into the subcutaneous environment. This formulation offers the ability to integrate multiple drugs in a single injection, the ability to deliver drugs for several weeks or months, and the ability to be removed if required in order to terminate the treatment. This ISFI formulation can be fine-tuned to deliver drugs at targeted release kinetics. Our lab is investigating this formulation for HIV prevention and treatment, as a multipurpose prevention technology (MPT) and for other indications including contraception.

Biodegradable Polymeric Solid Implants for Ultra-Long-Acting Drug Delivery

Our lab has developed an ultra-long-acting (ULA) biodegradable polymeric solid implant (PSI) fabricated using a new engineering process combining in-situ phase inversion and compression. This robust process allows fabrication of biodegradable solid implants that can have different shapes and sizes, can accommodate high drug payloads (up to 85 wt%), can accommodate multiple drugs in a single compact implant, and can provide sustained drug release over several months. This versatile platform technology can be applied to a wide range of indications that can benefit from sustained drug release over a prolonged period of time.

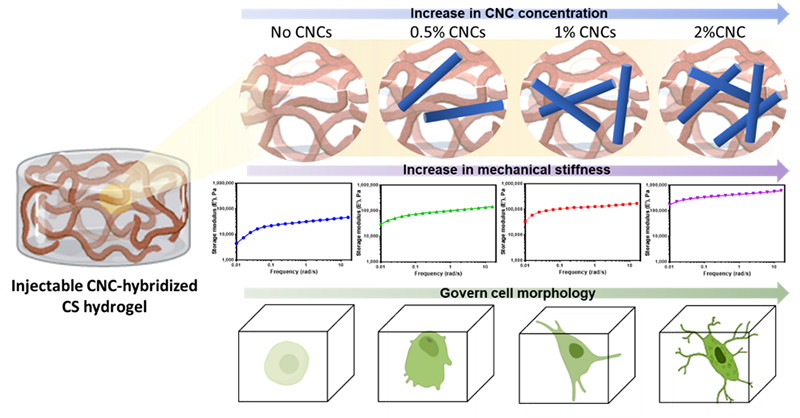

Thermo-/pH-Responsive Chitosan-Based Hydrogel for Tissue Regeneration Applications

Our lab has developed an injectable hydrogel with physical and mechanical properties that can mimic the bone microenvironment and promote bone regeneration. The injectable hydrogel is prepared with FDA-approved thermogelling biopolymers, chitosan and cellulose nanofibers/nanocrystals (CNFs/CNCs)). The chitosan solution can undergo sol-gel transition at body temperature, and CNFs/CNCs are used as an additive nanomaterial to enhance the mechanical properties of the chitosan gel and mimic bone tissue properties. Cellulose nanocrystals (CNCs) can significantly improve the gelation kinetics and mechanical properties of the injectable chitosan hydrogel. This novel chitosan-CNC based injectable and biodegradable scaffold can be administered as a stable solution containing osteoblast cells and can promote cell viability and transformation for bone and tissue engineering. This hydrogel is also being investigated as a scaffold for induced neural stem cells for treatment of glioblastoma multiforme (GBM).

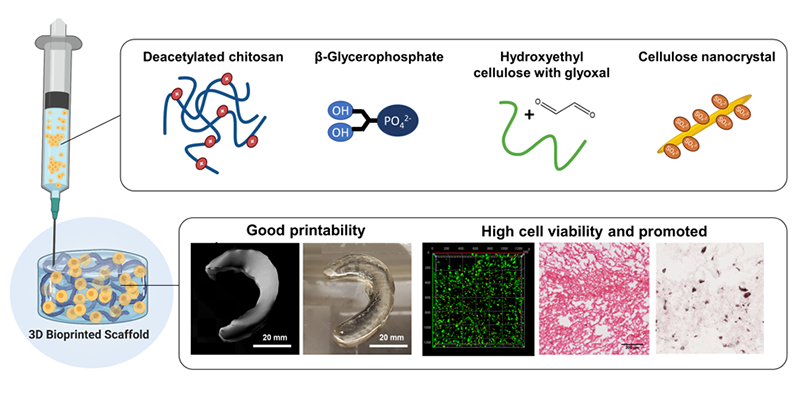

Cell-Laden Nanocellulose/ Chitosan-Based Bioinks for 3D Bioprinting

3D bioprinting has recently emerged as a very useful tool in tissue engineering and regenerative medicine. Our lab is developing a nanocellulose/chitosan-based bioink, that is compatible with a 3D extrusion-based bioprinting technology, to design and engineer constructs for bone tissue engineering and regeneration applications. These bioinks are biocompatible and printable at an optimized range of printing pressure that does not compromise cell viability, and the presence of CNCs promotes greater osteogenesis of MC3T3-E1 cells in chitosan scaffolds. The versatility of this CNCs-incorporated chitosan hydrogel makes it attractive as a bioink for 3D bioprinting to engineer scaffolds for bone tissue engineering and other therapeutic applications.

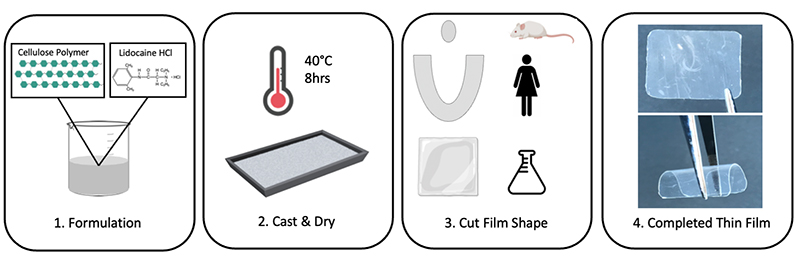

Mucoadhesive Biodisolvable Thin Film for the Treatment of Vestibulodynia

Our lab is developing a novel thin film technology for the treatment of Vestibulodynia (VBD), which is the most common cause of sexual pain, affecting 10 to 28% of reproductive aged women in the United States. This is another platform technology that can be applied to a wide range of women’s health indications including sexual pain.